Black Cat Wear Parts Expanding Distribution in Zambia and DRC

Black Cat Wear Parts is strategically building its distribution network in Zambia and the Democratic Republic of Congo to improve access to its advanced technology for the mining, construction and road maintenance industries.

Founded in 1968, Black Cat is among the world’s leading providers of heavy-duty wear parts, sold internationally through 250+ dealer partners.

The company’s comprehensive line of wear parts for ground-engaging tools has been repeatedly put to the test on the most demanding mine sites around the globe. Any terrain. Any scale. Any challenge. Black Cat is there for its customers.

Global Manufacturing

With three international manufacturing plants, Black Cat provides digging, ground penetration, protective and scraping components for open-pit, oil sands, and hard rock operations.

This includes a complete offering of teeth, blades, edges, lips, guards and adaptors to fit all leading makes and models of cable & hydraulic face shovels, excavators, dozers and earth moving equipment.

Their expertise and impact extend beyond replacement parts. Black Cat’s OEM components are used in factory line assemblies for some of the world’s most recognized brands. Custom capabilities have allowed Black Cat to meet the industry’s demands for innovation and excellence.

The Secret to Their Strength

Advanced metallurgy and engineered-to-purpose fabrication distinguish Black Cat wear parts. High-spec alloy steel is precisely heat-treated to provide optimum strength and durability. Computer-aided design and analysis ensure the perfect fit and reliable performance for every part.

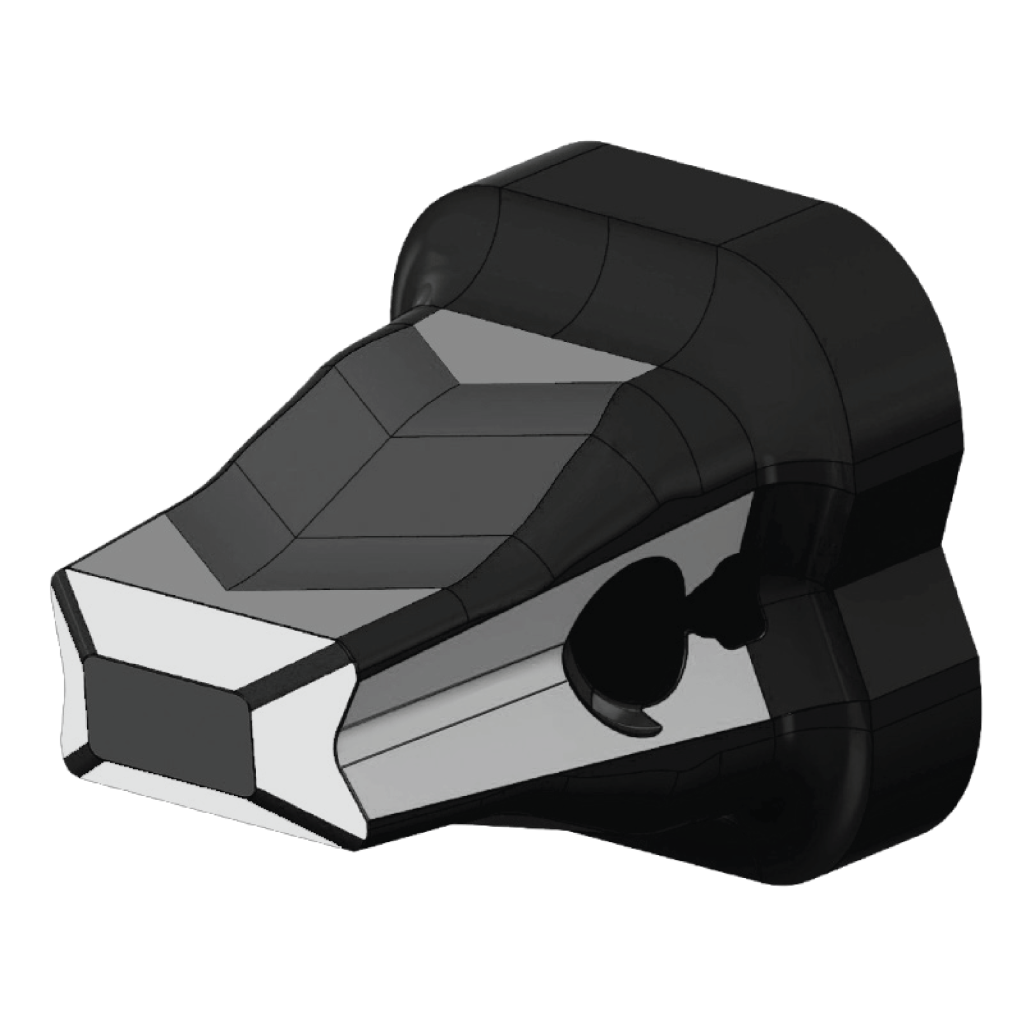

Innovation Leadership: Revolution® Hammerless Technology

For mine operators that place a high value on safety, simplicity and productivity, Black Cat’s patented Revolution® Hammerless GET solution lives up to its name.

This innovative system allows for faster, safer installation and removal of wear parts without the need for hammers or additional specialty tools.

Hammerless Pin & Lock

- The pin locks with a 180° clockwise turn using a socket wrench

- Accepts both imperial and metric sockets, with a female square drive on the opposite end.

- The lock and pin can be used on either side of the nose.

- Designed so that pin removal will pull out excess material around the pin head.