Conveyors are among the fastest and potentially most dangerous transport systems in a bulk handling operation. Although their safety and performance are critical to the operation’s success, their contribution to overall efficiency is often overlooked by both management and workers. The operational basics of belt conveyor systems are often a mystery to employees who have little understanding of the hardware installed and the performance expected from the components.

The knowledge gap is understandable. The focus of personnel at a bulk handling operation is on logistics and scheduling. The “care and feeding” of belt conveyors—meaning the adjustment, maintenance, and troubleshooting—greatly impacts safety and performance but is usually outside of the operator’s expertise. It’s not that they don’t care about conveyors, but the ongoing maintenance and service of these systems is often overshadowed or deprioritized in favor of other issues.

Low-Bid Process and Life Cycle Cost

Although companies usually do not explicitly state this policy, the Low-Bid Process is generally an implied norm embedded in the company’s culture. It encourages bidders to focus on maximizing load capacity while minimizing compliance with regulations, using the lowest-cost materials, components, and manufacturing processes available.

Maximizing material volume and minimizing system cost typically involves selecting the narrowest feasible belt that runs at the highest possible speed. This approach leaves little room for error and often results in chute plugging, excessive spillage, and a shorter equipment lifespan.

When companies focus only on price, the advantages are often temporary, and costs tend to increase over time, ultimately leading to losses. In contrast, when purchases are based on the lowest long-term cost (life-cycle cost), benefits typically continue to grow, and costs decrease, resulting in overall savings over time.

over the extended life and safety of the system.

Conveyor System Design Hierarchy

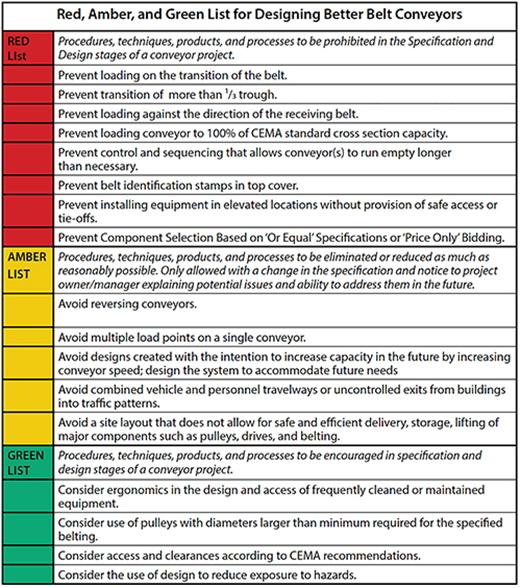

To safely maximize production, designers and engineers should approach the project with a clear set of priorities. Instead of merely meeting minimum compliance standards, the conveyor system should exceed all code, safety, and regulatory requirements by applying global best practices. By designing the system to reduce risk and prevent the escape and buildup of fugitive material, the workplace becomes safer and the equipment easier to maintain.

systems should exceed code, safety and regulatory requirements.

Life cycle costing should influence all component decisions. Be aware of project specifications that state “Specific Manufacturer Name / Or Equal.” Vaguely written “Or Equal” specifications are intended for competitive reasons and allow contractors to choose based on price without considering construction or performance. Instead, selecting based on Life Cycle Cost or Engineer-Approved Or Equal, and planning for future use of problem-solving components in the basic conveyor design, offers improved safety and access without increasing structural steel requirements or significantly raising overall costs. It also enables easier future system upgrades. Designing for future capacity increases from the start can expand options and help reduce future modification costs.

Life cycle costing should influence all component decisions. Be aware of project specifications that state “Specific Manufacturer Name / Or Equal.” Vaguely written “Or Equal” specifications are intended for competitive reasons and allow contractors to choose based on price without considering construction or performance. Instead, selecting based on Life Cycle Cost or Engineer-Approved Or Equal, and planning for future use of problem-solving components in the basic conveyor design, offers improved safety and access without increasing structural steel requirements or significantly raising overall costs. It also enables easier future system upgrades. Designing for future capacity increases from the start can expand options and help reduce future modification costs.

Designing Conveyor Upgrades for Safety

There is ongoing pressure from managers to boost production to meet customer demand. However, standards continue to tighten as government regulators remain strongly focused on worker safety, creating the need for equipment designs that are not just safe but optimized for safety (designed for safety). Personnel are the most valuable resource in any industrial operation. That’s why conveyor system designers are adding more functionality to their designs to enhance safety.

To minimize hazards in the workplace, operators use various methods, from requiring personal protective equipment (PPE) to installing the latest and safest equipment designs. When assessing system safety, improving efficiency and reducing risk can be achieved by applying a hierarchy of control methods to address hazards. Safety professionals generally agree that the most effective way to reduce risks is to eliminate the hazard through design. This often requires a higher initial capital investment than short-term solutions but provides more cost-effective and lasting results.

Examples of Eliminate by Design include longer, taller, and tightly sealed loading chutes to control dust and spillage, or heavy-duty primary and secondary cleaners to minimize carryback. By using hazard identification and risk-assessment methods early in the design process, engineers can develop the safest, most efficient system for the space, budget, and application. These designs reduce several workplace hazards while minimizing cleanup and maintenance, cutting down on unscheduled downtime and extending the life of the belt and the system itself.

Experienced engineers often recommend that operators hire an external firm to assess system requirements and design new equipment based on historical issues and specific application needs. An external perspective can usually identify potential hazards that might be missed by workers who encounter them daily.

Before the drafting phase, designers should define the goals of reducing injuries and exposure to hazards (such as dust and spillage) to boost conveyor uptime and productivity, and explore more effective solutions for ongoing operating and maintenance challenges. Designs should be forward-looking, surpassing compliance standards and improving operators’ ability to easily incorporate future upgrades in a cost-effective way by adopting a modular approach.

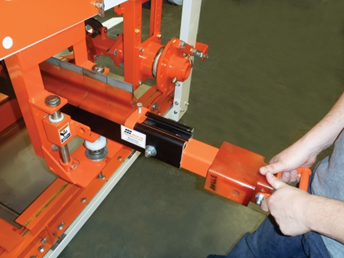

Combining Safety & Productivity To meet the demands for increased safety and better production, some manufacturers have introduced equipment designs that are not only built for safer operation and easier servicing but also reduce maintenance time. One example is an innovative line of heavy-duty conveyor belt cleaners, designed so the blade cartridge can be pulled away from the belt for safe access and replaced by a single worker

accessed safely and replaced by a single worker.

The same slide-out technology has been used in impact cradle designs. The systems are designed to allow operators to work on the equipment safely without disrupting the plane of motion. External servicing reduces confined space entry and eliminates reach-in maintenance, while enabling quicker replacements. The result is improved safety and efficiency, with less downtime.

Another example is a revolutionary new belt cleaner design that can eliminate the need for bulky urethane blades altogether. It is an innovative belt cleaning system that has received the Australian Bulk Handling Award in the “Innovative Technology” category for its design and potential benefits. The patented design provides an extended service life, low belt wear, significantly reduced maintenance, and improved safety, ultimately resulting in a lower cost of ownership.

Unlike conventional belt cleaners mounted at an angle to the belt, the unique cleaner is installed diagonally across the discharge pulley, creating a three-dimensional curve beneath the discharge area that matches the pulley’s shape. The innovative method has proven so effective that in many operations, previously essential secondary belt cleaners have become unnecessary, reducing both belt cleaning costs and service time.

Conclusion

Engineering safer conveyors is a long-term strategy. Although design accounts for less than 10 percent of a project’s total budget, Engineering / Procurement / Construction Management (EPCM) services can make up as much as 15 percent of the installed cost of a major project. Additional upfront engineering and applying a life cycle-cost methodology to selecting and purchasing conveyor components prove beneficial. By encouraging the use of the Hierarchy of Controls during planning, along with the Design Hierarchy during the design stage, the installation of an Evolved Basic Conveyor can be achieved. The system will likely meet modern production and safety regulations, with a longer operational life, fewer stoppages, and a lower operating cost.