Carl Hamm Pipes Pumps Solutions specialize in Turn-key Abstraction of water, whether it is a Virgen mine planning strategy or a flooded or closed mine we can offer Trunkey solutions. Chris Munnick, CEO of Carl Hamm PPS South Africa, is going the extra mile in looking for cost effective solutions to deliver the goods – or water, in this case. SA Mechanical Engineer found out how.

Carl Hamm PPS South Africa, a subsidiary of the privately owned Fourth Generation Family Business in Germany, recently added and began distributing Düchting pumps. An exciting development for Chris and team, Düchting pumps offer solutions many Southern African Mining companies are looking for – they can pump “Run of Mine” underground water to at High Pressures with less downtime and maintenance than is normally associated with this type of multistage pump.

“First Glance of a Düchting HPX range pump is they appear the same many other pumps on the market, but they can do so much more,” Chris says.

The difference starts with the rotational speed, clearances, and robust design.

There’s wide a range of Düchting pumps, but Chris is particularly excited about the multistage centrifugal HPXL, HPXU and HPXM pumps with their high efficiency and low life cycle costs – and an average MTBS of 25 000 working hours.

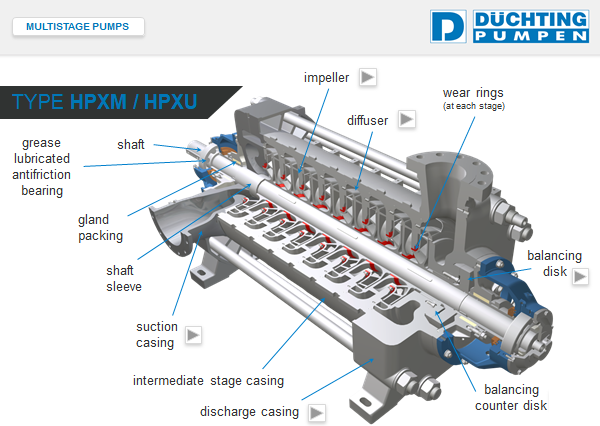

The HPXL, HPXM and HPXU pumps have a nominal pressure of up to 160 bars and flow of up to 3 500m3 per hour. The maximum density is up to 1 400 g/l and the PH value 0-14. They operate at a low speed so there is low wear, and they are available in almost any metal from cast iron to Super Duplex stainless steel.

4-pole pump for liquids with abrasive content – Maximum Density up to 1,400 g/l (e.g., brine) – Typical mining applications up to 5 % by – weight (approx. 50.000 ppm) – With low speed = low wear

The ring-section design includes axial thrust compensation, achieved using balancing discs and balancing counter discs, shaft sealing by stuffing box or mechanical seals, and flanges positionable in 90° steps. The pumps are manufactured according to DIN/ASME standards.

Tailor made solutions are available such as one or two connective shaft ends, single or double inlet suction and intermediate flanges at stage casing.

The pumps can handle contaminated, chemically neutral, or aggressive liquids with up to 10% solids.

“We can eliminate one of the biggest problems – we can handle “Run of Mine water”.

Over 2 000 units have been sold across the globe from the USA and Canada to China, the Philippines, Germany, and Poland. The experience of some of these users shows how impressive the performance of the pumps is.

A high-pressure type HPXM 50X3 pumping 720m3 per hour at 30 bar was supplied to a coal mine at Ibbenburen, Germany in 1988 and is still in operation. An HPXU 200X13 high pressure type pump was adapted to the needs of a coal mine in China and pumps 500m3 per hour at 93 bar. An HPXM 250X6 pump installed in a copper mine in Lubin, Poland was in use for 49 000 hours without a service.

“The pumps guaranteed efficiency of over 80%. And vastly reduce maintenance and downtime,” Chris says. Making them ideal for any mine whether it is operational or not.

The Market has asked for this Product for a long time,” Chris says. And now we can deliver it.

- “4-pole pump for liquids with abrasive content

- Maximum Density up to 1,400 g/l (e.g., brine)

- Typical mining applications up to 5 % by weight (approx. 50.000 ppm)

- Low speed = low wear”

PHONE:

+27 (0)83 488 0883

EMAILS:

jeanette@carl-hamm.co.za

admin@carl-hamm.co.za

ADDRESS:

2 Brickford Rd, Founders Hill, Kempton Park, Gauteng.

PO BOX 1492, Boksburg, Germiston,1460,

South Africa.